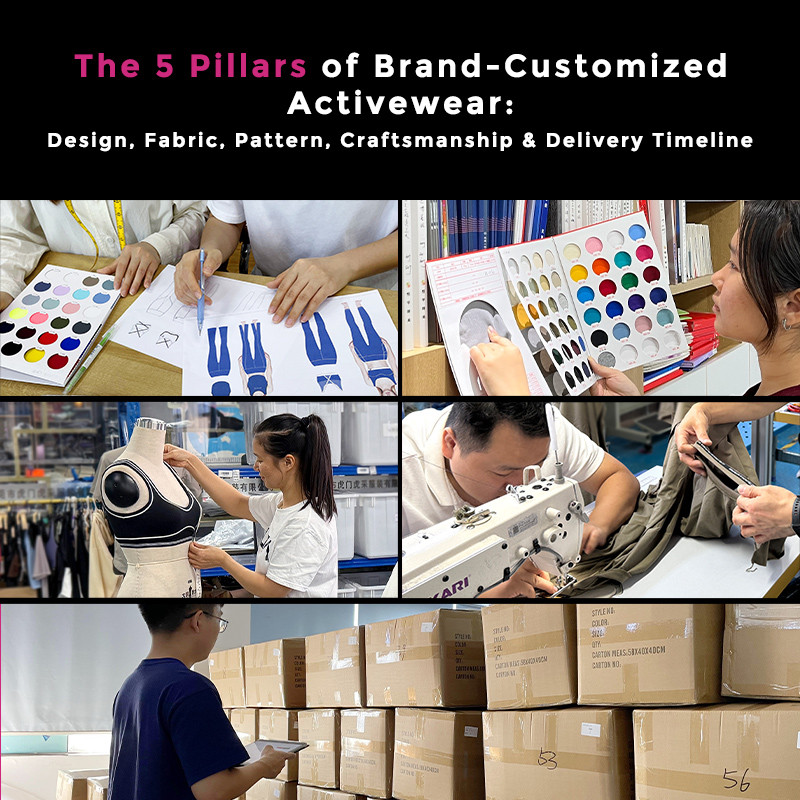

The 5 Pillars of Brand-Customized Activewear: Design, Fabric, Pattern, Craftsmanship & Delivery Timeline

- Share

- publisher

- sunny

- Issue Time

- Aug 8,2025

Summary

Discover the five OEM/ODM pillars that help premium brands create consistent, high-performance activewear.

For premium activewear brands, customization is not a luxury—it's a necessity. With rising consumer expectations around performance, sustainability, and style, buyers need manufacturing partners who offer more than just basic production.

At HUCAI, we've refined our OEM/ODM system around five core pillars that enable our clients to launch and scale sportswear collections efficiently—without compromising brand DNA.

1. Design: Where Vision Meets Feasibility

We support brand designers or creative teams with technical feasibility from Day 1. Whether you bring detailed tech packs or just inspirational images, our development team helps you translate vision into a ready-to-produce product.

✅ Key offerings:

- Style consulting for men’s/women’s collections

- Trim/hardware compatibility advice

- 3D rendering and pre-sample visuals

- Branding placement and logo execution testing

2. Fabric: Engineered for Movement and Identity

Fabric defines how your product feels, performs, and positions. We source high-grade performance fabrics and develop brand-specific options, such as cold-touch yoga blends, brushed compression jerseys, or lightweight quick-dry mesh.

✅ Fabric solutions:

- Access to 100+ tested activewear fabrics (recycled, stretch, sculpting)

- Custom dyeing and digital sublimation printing

- Fabric test reports for stretch, shrinkage, and colorfastness

- MOQ balancing for standard vs. exclusive materials

3. Pattern: Fit Consistency and Size Grading

Your fit is your fingerprint. That's why we provide full pattern development or adjust based on your block. Our team ensures ergonomic construction with Western, Middle Eastern, and hybrid body types in mind.

✅ Pattern services:

- Tech pack translation to factory-ready paper patterns

- Grading from XS–XXL or custom sizing tiers

- Pre-production fittings and tolerance testing

- Panel optimization for print or mesh integration

4. Craftsmanship: Where Function Meets Finish

In activewear, the smallest detail can make or break performance. Our skilled production teams combine digital cutting, precision sewing, and automated QC to deliver products that hold shape, endure sweat, and elevate style.

✅ Manufacturing capabilities:

- Flatlock, coverstitch, bonding, and zigzag reinforcement

- Tension testing for seams, elastics, and armholes

- Logo heat-transfer, embroidery, silicone print options

- Smart hanging systems + MES tracking for real-time accuracy

5. Delivery Timeline: Speed Without Sacrifice

We understand that brands move on retail calendars, not factory timelines. That's why we maintain an agile production system with forecasting flexibility, ensuring you never miss a launch window.

✅ Time management services:

- Sample delivery within 7–12 working days

- Bulk production from 25–35 days based on style complexity

- Dedicated merchandisers for calendar alignment

- Optional DDP shipping to selected markets

Build Custom Activewear That Performs and Delivers

Whether you're scaling an existing line or launching a niche capsule, HUCAI helps you build products that match your market, your brand, and your timing.

Contact us to explore how our five-pillar OEM/ODM support can drive your next high-performance activewear collection